Can Conveyor

Side Belt Transfer

The side belt transfer is used for downed bottle elimination, depucking, and for code dating applications. This unit is adjustable to various product widths.

The products transported on side belt transfers have ranged from glass, cans, and plastic containers, to cartons and shrink-wrapped bundles.

The side belt transfer can be designed to convey different package shapes, like this device that transfers small bottles.

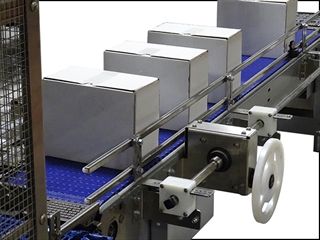

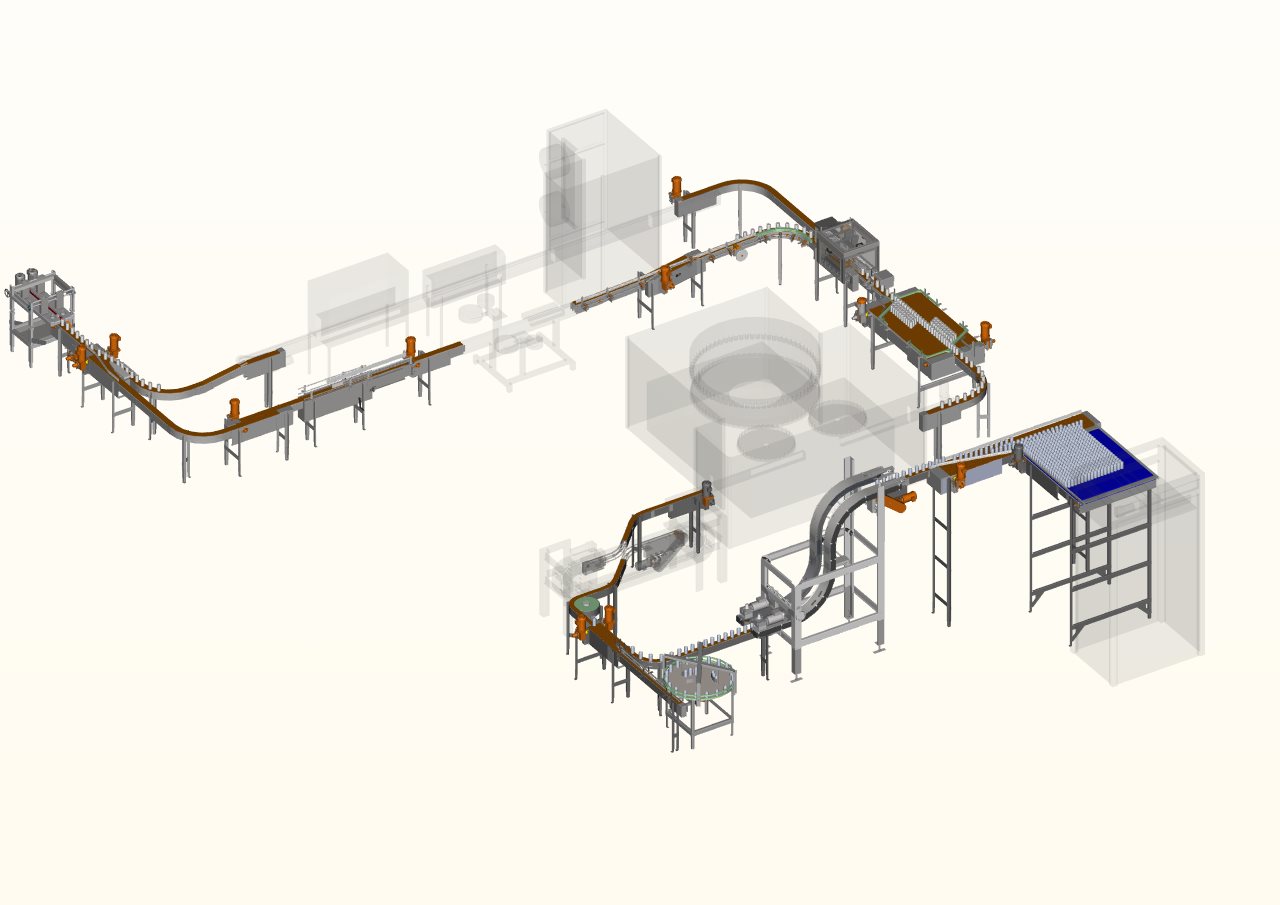

Tabletop Conveyor

MCE modular tabletop conveyor provides many solutions for transporting products through the various elevation and directional changes of a production line. Designed as a prefabricated modular stock program, these complete conveyor systems are fully adaptable to many applications making MCE ideal for existing manufacturing configurations or completely new projects.

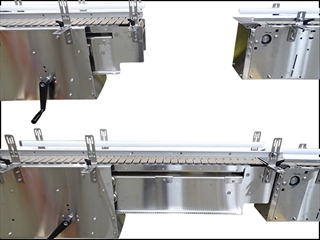

Conveyor Retractable Gate

The conveyor retractable gate provides personnel, fork trucks, and other moving equipment unrestricted movement through the production floor.

The conveyor retractable gate is designed to horizontally retract into itself and is operated by a manual hand crank, with standard openings ranging from 30" up to 60''.

Adjustable Guide Rails ~ Rapid-Rail®

Rapid-Rail® is engineered to simplify changeovers on the packaging line. Rapid-Rail® offers a single-point, easy-to-use hand adjustment of guide rails to accommodate multiple package sizes on the same piece of equipment. Now several points along the conveyor, over a long distance, can be controlled from one location on the line.

Diverter Gate

The Divert Gate is a one to two and one to three-lane divert operation offered as part of the Modular Conveyor Express line. The units have adjustable guide rail openings as well as elevation adjustments. Divert Gates are shipped fully assembled and include configurable mounting hardware for fast field installation.

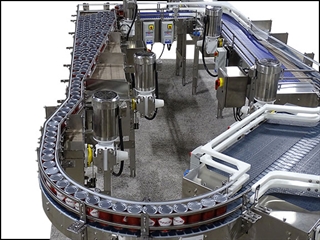

Re-Flow Accumulation Table

MCE’s Re-Flow accumulation conveyor allows for smooth in-line product accumulation during downstream downtime events or changeovers. Utilizing a small footprint compared to the large storage capacity, the recirculating conveyor has the ability to accumulate and single-file products, controlling product flow to the next manufacturing process. The ability to recirculate products during a downstream pause or backup is critical to overall production efficiency.

Single Filer

MCE’s single filer is a low-pressure conveyor designed to gently move products from mass-flow or accumulation and return them to a single file for continuous production throughput. Commonly paired with MCE’s re-flow accumulation table, the single filing conveyor arranges product accumulation zones into a single line as production rates increase during discharge offering optimum running performance.

Gripper Elevator

The gripper elevator has the advantage of securely elevating or lowering products using very little floor space. This unit firmly but gently grips the product from the same elevation as the in-line conveyor and provides continuous transport through an elevation change. Grippers then release the product through a seamless discharge onto a take-away conveyor.

Rotary Table

(Available in 36", 48", and 60")

Rotary accumulation tables or unscrambling tables are designed to support a variety of conveyor system requirements. Designed for a small footprint these accumulation tables are often used with round containers such as bottles to accumulate bulk or unscramble bulk products so that they can be discharged in a single file line. An efficient process to balance production rates, a buffer space accumulates product allowing production to continue while downstream product is temporarily stopped.