Bi-Directional Accumulation Table

About MCE's Bi-Directional Accumulation Table

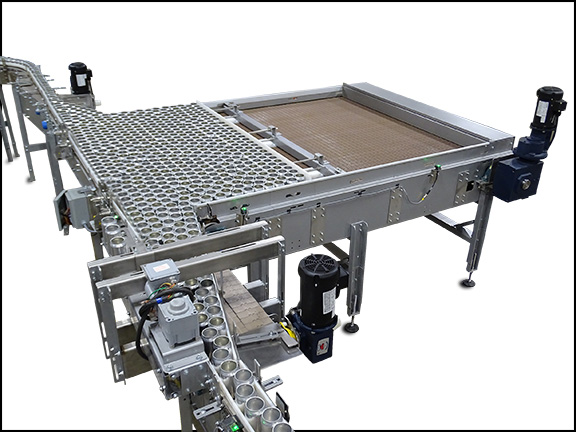

MCE's bi-directional accumulation table is a solution for accumulation pressure problems. Line production can be stopped at any point and may be interrupted by a product blockage, machine adjustment, or malfunction. The bi-directional table allows time for the downstream blockage to clear while storing products to keep upstream production moving.

This temporary storage space allows for accumulation relief during a downstream pause which is critical for keeping overall production efficiency. Sensors indicate when products need to start being stored and then slowly accumulate on the table. When it is time for production to continue, the products are gently pushed forward feeding them back into the production line at a proper speed to prevent tipping.

- MCE's bi-directional design has a standard width of 6' and ranges from 5'-10' long (ft)

- Can be made with different belts depending on the specific application

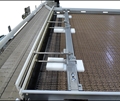

- MCE offers multiple designs of discharge conveyors on accumulations systems

- Photos

- Videos

- Documents

- Industries

- Applications

- Bottles

- Cans

- Jars

(Round non-tapered products)

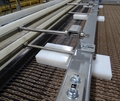

Easy Installation

MCE conveyor solutions are extremely streamlined. MCE ships conveyor projects in assemblies with drives, reducers, wearstrips, returns, guide-rails and brackets already installed. Bolting the assemblies together, installing the chain and fine tuning guide-rails to fit the product or package are the only on site installation steps required, making MCE coneyor solutions capable of maximizing productivity at no expense of extra resources.