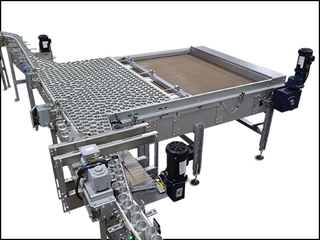

Conveyor Accumulation Solutuions

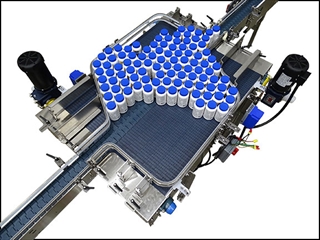

An ideally timed product flow optimizes your production output. The true efficiency of the production line is the output at the end of the line. Accumulation is the key to making high speed lines work successfully to maximize throughput. MCE accumulation solutions lets the line operate at this ideal timing. Accumulation is required in high speed production lines to make sure that the generating unit continues to run during backups of downstream equipment. A reliable accumulation system results in more production and less waste.

Three main considerations when researching accumulation solutions

- Consider the product weight, shape and packaging. Is the product stable when conveyed? Can the product handle back pressure to accumulate? The type of product may be the defining factor in the best accumulation choice for the application.

- Determine the area available for the equipment. In some production floor layouts, there may be conveyors overhead which would eliminate most of the vertical accumulation solutions. Similarly, the floor layout may be already crowded and the only way to accumulate is to go up.

- Calculate the amount of accumulation time needed. This will affect either the footprint or the height of the equipment, depending on the type of equipment.

MCE has several modular equipment options for solving various types of production needs.