Adjustable Guide Rails ~ Rapid-Rail®

Exclusively for new or existing MCE Conveyor ~ ONLY

About MCE Adjustable Guide Rails

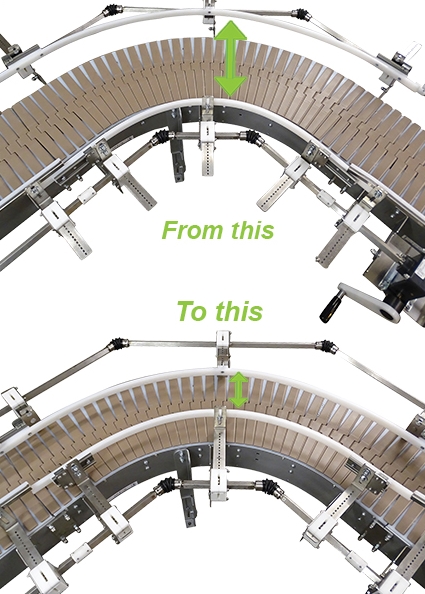

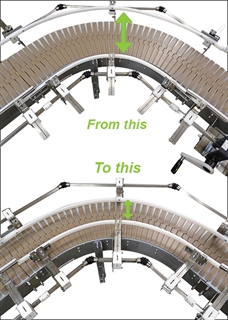

Rapid-Rail® is engineered to simplify changeovers on the packaging line. Rapid-Rail® offers a single point, easy-to-use hand adjustment of guide rails to accommodate multiple package sizes on the same piece of equipment. Now several points along the conveyor, over a long distance, can be controlled from one location on the line.

MCE employs a simplified, more economical design on Rapid-Rail® that limits the number of moving parts. With a repeatable system, it’s easy to fine-tune the path as products go through the turn. The new design also enables operators to add a motor and control any adjustments right from a conventional control system.

The value to packaging customers is multi-fold. Time savings with MCE’s Rapid-Rail® is HUGE! On a long carton conveyor line with numerous guard rail brackets, it could take several hours for rail adjustments to changeover to different size cartons. With Rapid-Rail®, all adjustments are made from only a few locations and affect all points along the line. Change from 32 oz. bottles to 16 oz. bottles in a minute with Rapid-Rail®. The equipment works equally well with any type of grocery packaged product.

Exclusively for new or existing MCE Conveyor ~ ONLY

- Photos

- Documents

- Industries

- Applications

- Bottles

- Cans

- Cartons

- Glass

- Jars

- PET

- Pucks

Easy Installation

MCE conveyor solutions are extremely streamlined. MCE ships conveyor projects in assemblies with drives, reducers, wearstrips, returns, guide-rails and brackets already installed. Bolting the assemblies together, installing the chain and fine tuning guide-rails to fit the product or package are the only on site installation steps required, making MCE coneyor solutions capable of maximizing productivity at no expense of extra resources.