MCE Expands Product Line with New Bi-Directional Accumulation Table

June 07, 2023

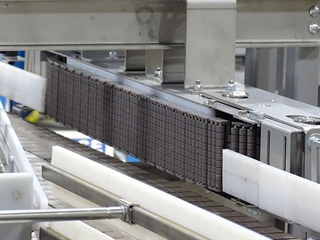

MCE continues to expand its complete line of conveyor solutions with its newest piece of equipment, the Bi-Directional Accumulation Table. This conveyor was engineered specifically for lines running round, non-tapered products at speeds around 500 PPM.

“Accumulation conveyors are essential for efficiency on high-speed production lines, and the more tailored the accumulation solution is to the line’s requirements, the greater ROI it delivers,” says Darrick Prill, Engineering Manager at Nercon, MCE’s parent company. “The Bi-Directional Accumulation Table’s capabilities and price point are ideally suited for mid- and small-market manufacturers in industries such as beverages, personal care, pharmaceuticals, and household cleaning products.”

Streamlining Design = Pricing Benefit

![]() Between the Bi-Directional conveyor’s initial concept and its launch, the product team engineered the design to deliver high quality and performance at a lower assembly cost, achieving a 40% reduction in manufacturing expenses during the process. “The new Bi-Directional Table is based on 47 years of experience developing reliable, durable, and efficient bi-directional accumulation tables,” says Jeff Falash, Research and Development & Field Services Manager at Nercon. “The straightforward, lightweight design costs less to build, with no trade-off in quality or performance. It’s simply a smart design for the applications it will be used for.”

Between the Bi-Directional conveyor’s initial concept and its launch, the product team engineered the design to deliver high quality and performance at a lower assembly cost, achieving a 40% reduction in manufacturing expenses during the process. “The new Bi-Directional Table is based on 47 years of experience developing reliable, durable, and efficient bi-directional accumulation tables,” says Jeff Falash, Research and Development & Field Services Manager at Nercon. “The straightforward, lightweight design costs less to build, with no trade-off in quality or performance. It’s simply a smart design for the applications it will be used for.”

Click the Bi-Directional Table’s sell sheet to view specifications.

MCE Bi-Directional Accumulation Table advantages:

- High product rate

- 90% of the table is usable

- Comb transition to run-by conveyor provides exceptional product stability

- Weighted adjustable sweep arm ensures no product is left behind

- Simple control scheme reduces cost and maintenance complexity

- Take-up design minimizes maintenance and allows for quick adjustment to compensate for any chain stretch during normal operation

- Available in Dry Levels 1 and 2, and Washdown

- Small footprint versus its large storage capacity

- Prepped for electrical controls

Design Features

To minimize line disruptions, MCE’s Bi-Directional Accumulation Table integrates with any of three jam correction options that can be selected depending on price point and the size of the facility’s operator team. Click the icon to watch a video.

- Prime Control – a maintenance-free, low-cost option that is 95%-99% effective in correcting jams by keeping the funnel point filled using sensors. This may require an additional conveyor length to act as a buffer to smooth out flow and minimize high-low cycling.

|

Powered Side Rail |

Ships in 3-4 Weeks Standard

The new Bi-Directional Accumulation Table is pre-engineered with common components in stock, so it typically ships in three to four weeks. Though MCE has several similar accumulation solutions such as the Reflow Table and Rotary Table, the Bi-Directional Table offers advantages over each depending on the shape, size, and weight of the product.

Distributors, if you’d like to talk with an MCE expert about the Bi-Directional Accumulation Table’s capabilities and ideal use cases, contact us online or call 844-293-2816. We’d love to talk with you about how this innovative conveyor fits into your customer solutions.