ARB™(Activated Roller Belt™) Conveyor System

About MCE Angled Roller Belt™ (ARB™) Conveyor

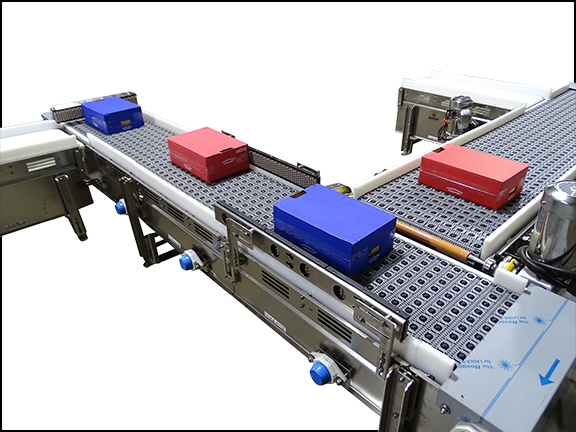

Angled Roller Belt (ARB™) also referred to as Activated Roller Belt™, is a technology patented by Intralox. This ARB™ technology allows packages to maintain a uniform position without the use of rails for alignment, which not only reduces equipment costs, but also minimizes labor costs in clearing jams or correcting stoppages. The ARB™ concept is to engage the rollers by means of a friction surface located beneath the belt.

Attributes:

Flexibility: ARB™ belting is modular in design and repairs can be made by pulling the pin and exchanging the necessary section.

Adaptability: These systems can handle a variety of package shapes and sizes.

Speed: Packages have been tested to travel at 220 packages per minute.

Reliability: Without guide rails, gating and pushers, these systems show a significant reduction in break-downs and jams.

Low Maintenance: Few components result in less maintenance.

- Photos

- Videos

- Industries

- Applications

- Boxes

- Cartons

- Cases

- Trays

Easy Installation

MCE conveyor solutions are extremely streamlined. MCE ships conveyor projects in assemblies with drives, reducers, wearstrips, returns, guide-rails and brackets already installed. Bolting the assemblies together, installing the chain and fine tuning guide-rails to fit the product or package are the only on site installation steps required, making MCE coneyor solutions capable of maximizing productivity at no expense of extra resources.