Mass Flow Conveyor

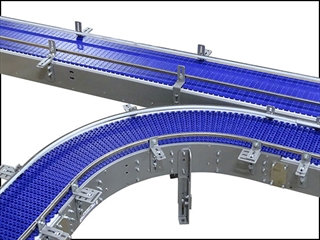

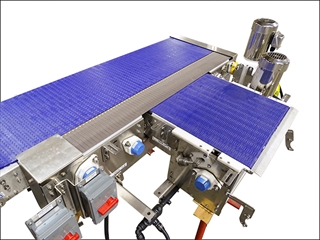

MatTop Conveyor

The side belt transfer is used for downed bottle elimination, depucking, and for code dating applications. This unit is adjustable to various product widths.

The products transported on side belt transfers have ranged from glass, cans, and plastic containers, to cartons and shrink-wrapped bundles.

With a wide range of side-flexing plastic chain to fit most applications, MCE's modular MatTop conveyors provide long life and high impact resistance. Moving products through inclines, declines, and production line curves, the sprocket-driven thermoplastic belts ensure positive tracking while providing quiet, smooth, trouble-free performance.

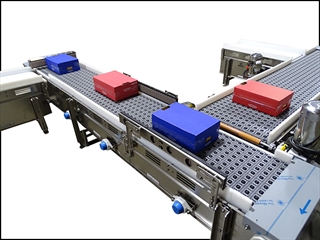

Dynamic Transfer Section

The Dynamic Transfer Section allows manufacturers to make tighter turns in a smaller floor space. Capable of handling a variety of product sizes, types, and shapes, the dynamic transfer section features a smooth, live transfer without the use of a dead plate, keeping even the last products moving and ensuring product stability and integrity.

Micro-Transfer Conveyor

Micro-Transfer Conveyors replace fixed deadplates by providing smooth product transitions between conveyors and other equipment for a wide range of product handling applications. They are especially effective with unstable or irregularly shaped products that can hang up when transferring between conveyor sections and other packaging machinery.

ARB™(Activated Roller Belt™) Conveyor System

Activated Roller Belt™also referred to as Angled Roller Belt (ARB™), is a technology patented by Intralox. This ARB™ technology allows packages to maintain a uniform position without the use of rails for alignment, which not only reduces equipment costs, but also minimizes labor costs in clearing jams or correcting stoppages. The ARB™ concept is to engage the rollers by means of a friction surface located beneath the belt.

Diverter Gate

The Diverter Gate is a one-to-two and one-to-three-lane divert operation offered as part of the Modular Conveyor Express line. The units have adjustable guide rail openings as well as elevation adjustments. Divert Gates are shipped fully assembled and include configurable mounting hardware for fast field installation.

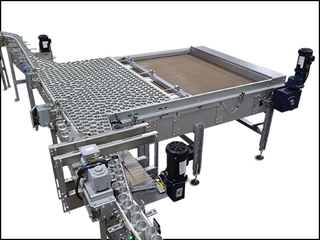

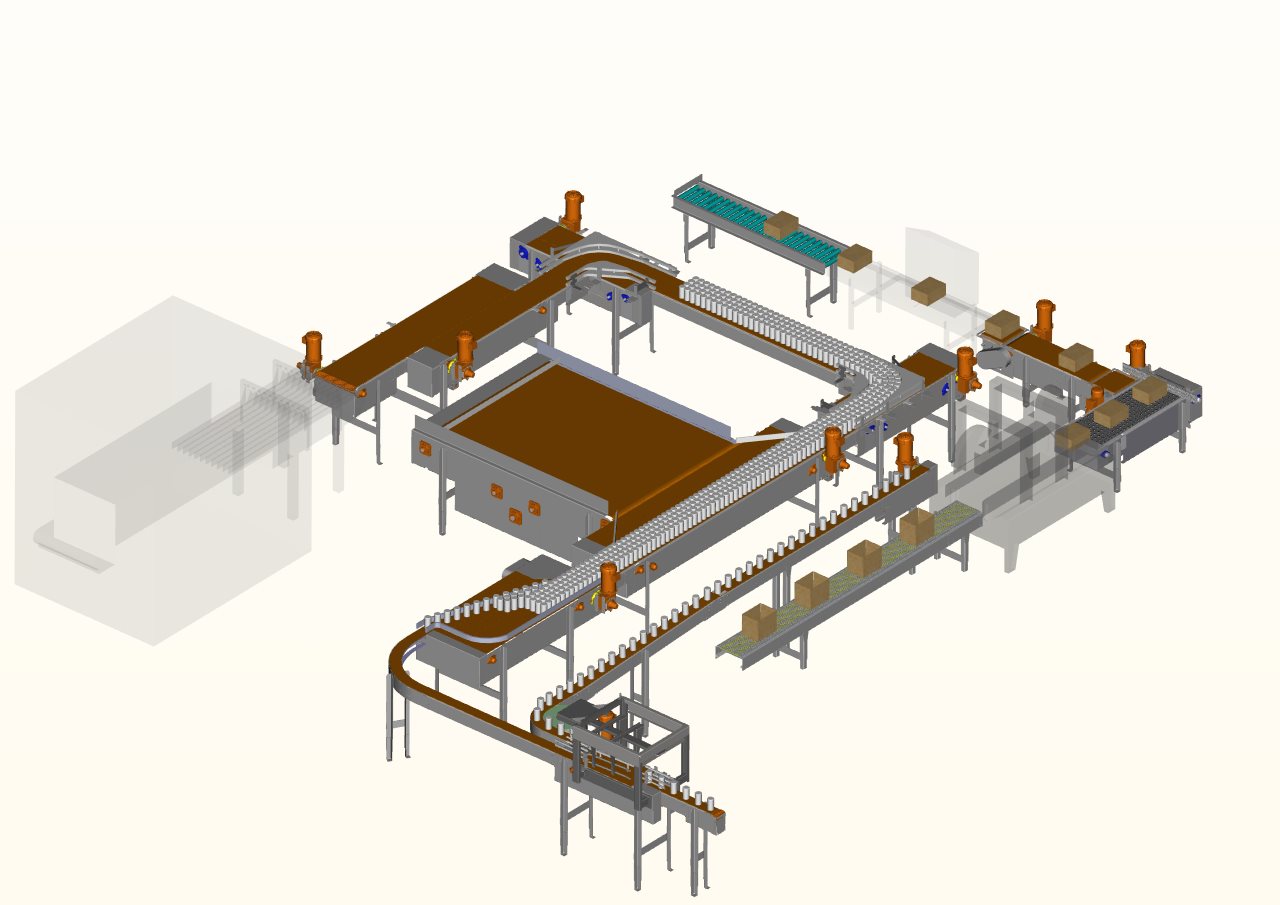

Bi-Directional Accumulation Table

MCE's bi-directional accumulation table is a solution for accumulation pressure problems. Line production can be stopped at any point and may be interrupted by a product blockage, machine adjustment, or malfunction. The bi-directional table allows time for the downstream blockage to clear while storing products to keep upstream production moving.