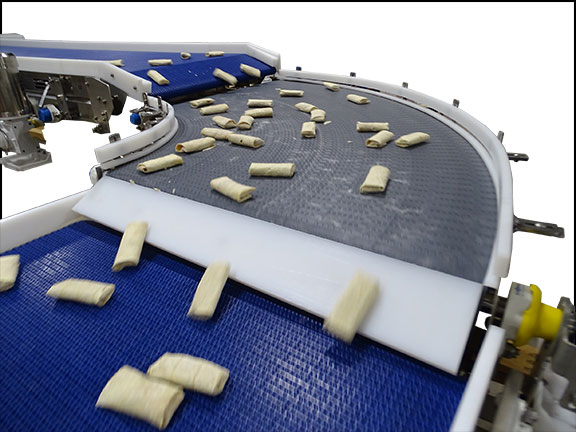

Conveyor Systems for Snack Food and Bakery Industries

The Challenges

Snack-food and bakery manufacturers need to optimize production for capacity, reduce downtime by maintaining greater efficiency and keep costs down while still factoring in strict food-safety regulations. Snack food and bakery companies looking to purchase conveyors must analyze several criteria. Easier and more predictable sanitation and repairs, quieter equipment, and improved safety and durability are factors to keep in mind.

Conveyor Solutions

MCE’s conveyors and conveying equipment for transporting food packages provide a wide range of equipment options to help production lines run at peak efficiency.

- Sanitary MatTop, Belt, and TableTop Conveyor Systems - with optional clean-out holes

- Rapid-Rail®

- Accumulation Tables

- Diverter Gate

- Micro-Transfer Conveyor

- Gripper Elevator

We offer several environmental packages for protection in wet facilities where washdown is required.

MCE’s modular conveyor solutions are suited to handle many product variants. Flexible and easy to assemble, quick reconfiguration for new projects or existing production lines can increase new product offerings.

- Product Experience

- Conveyor Applications

- Bars

- Bulk Ingredients

- Cakes

- Cereal

- Chips

- Cookies

- Dough and Bread

- Hard and Soft Shells and Pastries

- Ice Cream Cones

- Pies

- Snack Mixes

- Wafers and Crackers

- Accumulating

- Merging

- Dividing

- Inclining

- Vertical Conveying

- Lapping

- Depositing

- Rejecting

- Reclaiming